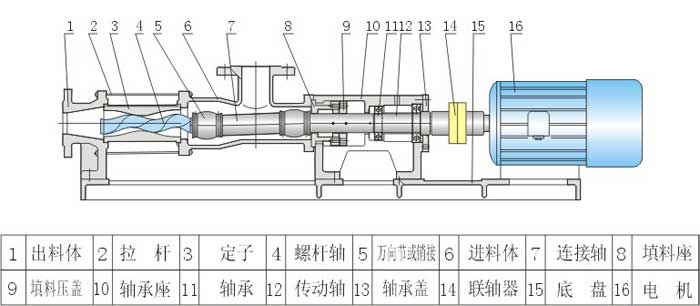

G-type hygiene food grade screw pump is to use screw rotation to suck and discharge liquid. The middle screw is the driving screw, which is driven by the prime mover. The screw on both sides is the driven screw, which rotates in the opposite direction with the driving screw. The screw threads of driving and driven screws are double headed. Due to the mutual engagement of the screws and the close cooperation between the screw and the inner wall of the liner, one or more sealing spaces are formed between the suction and discharge ports of the pump. With the rotation and meshing of the screw, a sealing space is formed at the suction end of the pump. The liquid in the suction chamber is sealed into it, and the liquid is continuously pushed from the suction chamber along the screw axial direction to the discharge end. The liquid in each space is continuously discharged, just as a nut is continuously pushed forward when the screw thread rotates. This is the basic working principle of the screw pump.

The characteristics of G-type screw pump for hygienic food are as follows

1. The spiral sealing line in contact with the stator and rotor completely separates the suction chamber from the discharge chamber, so that the pump has the same isolation function as the valve;

2. Multiphase mixed transportation of liquid, gas and solid can be realized;

3. The volume of the fluid in the pump does not change and there is no turbulence, agitation and pulsation;

4. The volume cavity formed by the elastic stator can effectively reduce the wear of the medium containing solid particles;

5. The viscosity of the input medium can reach 50000mpa · s and the solid content can reach 50%;

6. The flow rate is directly proportional to the speed. With the help of the governor, the flow can be automatically adjusted and the forward and reverse transmission can be realized.

The G-type screw pump has the following advantages:

Compared with centrifugal pump, screw pump does not need to install valve, and the flow is stable and linear flow;

Compared with plunger pump, screw pump has stronger self-priming ability and higher suction height;

Compared with diaphragm pump, screw pump can transport all kinds of mixed impurities, such as medium containing gas and solid particles or fiber, as well as various corrosive substances;

Compared with gear pump, screw pump can transport high viscosity materials;

Different from plunger pump, diaphragm pump and gear pump, screw pump can be used for reagent filling and metering.

Transportation of industrial sewage, domestic sewage and muddy water containing solid particles and short fibers, especially used in oil-water separator

Plate and frame filter press equipment, etc.

Shipbuilding Industry: ship bottom cleaning, oil and water, oil residue, oil sewage ring transportation.

Petroleum Industry: transportation of crude oil, mixture of crude oil and water, mixture of coalfield gas and water, injection of polymer into formation, etc.

Medicine, daily chemical: all kinds of thick paste, emulsion, various ointment cosmetics

Food can industry: all kinds of sticky starch, distiller's grains, grain product residue, all kinds of sauce, pulp, solid slurry

Construction industry: cement mortar, lime slurry, coating, paste spraying

Mining industry: solid particles, groundwater, sewage slurry water in the mine

Chemical industry: all kinds of suspensions, oils, gels and adhesives

Printing and papermaking: PVC polymer paste of high viscosity ink and wallpaper, pulp of various concentrations and short fiber pulp

Industrial boilers and power plants: coal water slurry transportation