1、 G series stepless speed regulation screw pump product overview:

Stepless speed regulation is to increase the function of stepless speed regulation on the basis of the original G-type screw pump. Stepless speed control screw pump is also the use of motor to adjust the speed, and electromagnetic speed control screw pump the only difference is that the former is manual, but the latter is by magnetic field. The above two kinds of screw pump equipped with such special motor is to adjust the flow and pressure of the water pump to achieve the required standards.

The relationship between flow and speed is linear. Compared with the screw pump with low speed, the high speed screw pump can increase the flow and head, but the power is obviously increased. The high speed accelerates the wear between the rotor and stator, which must make the screw pump fail prematurely. Moreover, the length of the stator and rotor of the high-speed screw pump is very short, which is easy to wear, so the service life of the screw pump is shortened. Through the reducer or stepless speed regulation mechanism to reduce the speed, so as to keep the exploration speed within a reasonable range of 300 rpm. Compared with the high-speed running screw pump, the service life can be prolonged several times.

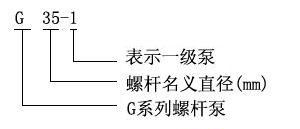

2、 Model meaning

model | pressure 0.3Mpa | pressure 0.6Mpa | Adjustable revolution | ||||||

revolutions (r/min) | flow (m3/h) | Motor power (kw) | revolutions (r/min) | flow (m3/h) | Motor power (kw) | revolutions (r/min) | flow (m3/h) | Motor power (kw) | |

G20-1 | 960 | 0.96 | 0.75-6级 | 960 | 0.8 | 0.75-6级 | 125~1250 | 0.1~1.5 | 1.1 |

720 | 0.8 | 0.55-8级 | 720 | 0.5 | 0.75-8级 | ||||

510 | 0.4 | 0.55-4级/齿轮箱 | 510 | 0.3 | 0.75-4级/齿轮箱 | ||||

G25-1 | 960 | 2.4 | 0.75-6级 | 960 | 2 | 1.5-6级 | 125~1250 | 0.1~3 | 1.5 |

720 | 1.5 | 0.55-8级 | 720 | 1.27 | 1.1-8级 | ||||

510 | 1.08 | 0.55-4级/齿轮箱 | 510 | 0.9 | 1.1-4级/齿轮箱 | ||||

G30-1 | 960 | 3.6 | 1.5-6级 | 960 | 3 | 2.2-6级 | 125~1250 | 0.2~4 | 2.2 |

720 | 2.28 | 1.1-8级 | 720 | 1.9 | 1.5-8级 | ||||

510 | 1.63 | 1.1-4级/齿轮箱 | 510 | 1.35 | 1.5-4级/齿轮箱 | ||||

G35-1 | 720 | 4.8 | 2.2-8级 | 720 | 4.04 | 3-8级 | 125~890 | 0.3~5 | 3 |

510 | 3.36 | 1.5-4级/齿轮箱 | 510 | 2.8 | 2.2-4级/齿轮箱 | ||||

380 | 1.92 | 1.1-4级/齿轮箱 | 380 | 1.60 | 1.5-4级/齿轮箱 | ||||

G40-1 | 510 | 6.8 | 2.2-4级/齿轮箱 | 510 | 5.6 | 3-4级/齿轮箱 | 125~890 | 0.3~10 | 4 |

380 | 5.1 | 1.5-4级/齿轮箱 | 380 | 4 | 2.2-4级/齿轮箱 | ||||

252 | 2.65 | 1.1-6级/齿轮箱 | 252 | 2.2 | 1.5-6级/齿轮箱 | ||||

G50-1 | 510 | 13.8 | 4-4级/齿轮箱 | 510 | 11.5 | 5.5-4级/齿轮箱 | 80~750 | 1~18 | 5.5 |

380 | 10.2 | 4-4级/齿轮箱 | 380 | 7.5 | 5.5-4级/齿轮箱 | ||||

252 | 5.6 | 3-6级/齿轮箱 | 252 | 4.4 | 5.5-6级/齿轮箱 | ||||

G60-1 | 510 | 20.8 | 7.5-4级/齿轮箱 | 510 | 16 | 11-4级/齿轮箱 | 63~630 | 1~20 | 11 |

380 | 15.6 | 7.5-4级/齿轮箱 | 380 | 12 | 11-4级/齿轮箱 | ||||

252 | 7.8 | 5.5-6级/齿轮箱 | 252 | 6 | 7.5-6级/齿轮箱 | ||||

G70-1 | 510 | 26 | 11-4级/齿轮箱 | 510 | 20 | 11-4级/齿轮箱 | 56~560 | 1~22 | 11 |

380 | 17 | 7.5-4级/齿轮箱 | 380 | 13 | 11-4级/齿轮箱 | ||||

252 | 9.1 | 7.5-6级/齿轮箱 | 252 | 7 | 7.5-6级/齿轮箱 | ||||

G85-1 | 380 | 32 | 11-4级/齿轮箱 | 380 | 25 | 15-4级/齿轮箱 | 37~370 | 2~24 | 15 |

252 | 21 | 7.5-6级/齿轮箱 | 252 | 16 | 11-6级/齿轮箱 | ||||

189 | 11 | 5.5-8级/齿轮箱 | 189 | 8 | 11-8级/齿轮箱 | ||||

G105-1 | 380 | 80 | 15-4级/齿轮箱 | 380 | 65 | 22-4级/齿轮箱 | 29~290 | 3~50 | 22 |

252 | 44 | 15-6级/齿轮箱 | 252 | 34 | 22-6级/齿轮箱 | ||||

189 | 29 | 11-8级/齿轮箱 | 189 | 22 | 15-8级/齿轮箱 | ||||

G135-1 | 380 | 132 | 37-4级/齿轮箱 | 380 | 120 | 45-4级/齿轮箱 | 18~180 | 3~56 | 45 |

252 | 95 | 30-6级/齿轮箱 | 252 | 80 | 37-6级/齿轮箱 | ||||

189 | 65 | 18.5-6级/齿轮箱 | 189 | 53 | 30-8级/齿轮箱 | ||||

Scope of application:

petroleum industry

Chemical and pharmaceutical

Environmental Engineering

Mineral Engineering

food industry

Paper industry

Heavy oil transportation oil and gas mixed transportation oil water separation and waste oil recovery system sewage treatment polymer transportation

All kinds of pastes, emulsions, suspensions, gas and solid liquids, media that can't be agitated and sheared

Equipment for transporting dewatered sludge, flocculant and its chemical agent, dosing, refueling water separation and waste gas desqualification coal water slurry equipment and production equipment for conveying titanium dioxide, kaolin, calcium carbonate, etc. rotating fluid, filter feeding, chemical feeding and grouting electrolyte treatment of dairy juice, fruit paste, vegetable paste, meat paste and condiment, beer and brewing raw materials equipment Stoichiometric pulping and wastewater treatment in coating and coloring processes

1. Transport high viscosity medium.

2. Conveying medium containing solid particles or fibers.

3. Continuous, stable pressure and no periodic pressure fluctuation are required.

4. Small agitation and no damage to the inherent structure of the medium to be transported.

5. Low noise.