Product overview

KCB gear oil pump is suitable for transporting all kinds of oil, such as crude oil, diesel oil and lubricating oil. Copper gear can be used to transport low flash point liquid, such as gasoline, benzene, etc. Medium temperature is not more than 70 ℃, if you need to use a high temperature resistant pump, you can contact the unit with high temperature resistant materials. The operating temperature of the high temperature resistant pump is less than 300 ℃, and the viscosity is 5 × 10-5 ~ 1.5 × 10-3 m2 / s. 2CY gear lubrication pump is mainly used for conveying lubricating oil in lubrication system of various mechanical equipment. It is used to transport lubricating oil with viscosity below 10. E (75c. S.T) and temperature below 300 ℃. Stainless steel gear pump can transport edible oil, beverage, etc. The structure of this series pump is simple and compact, and it is convenient to use and maintain.

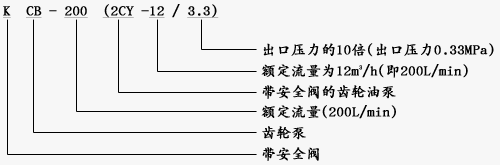

Model meaning

1、 KCB gear oil pump usage Description:

KCB gear pump is suitable for conveying all kinds of oil, such as heavy oil, diesel oil and lubricating oil. With copper gear, it can transport low-point liquid, such as gas oil and benzene, so it is called gear oil pump. Stainless steel gear pump can transport drinks and corrosive liquids. The viscosity is 5 × 10 - 5 ~ 1.5 × 103m2 / s. The temperature is not high at 70 ℃. If it is necessary to transport high temperature liquid, please use high temperature resistant gear oil pump for single-stage single oil suction pump, which can transport liquid below 300 ℃.

2、 Features of KCB gear oil pump:

1. The electric oil well pump has the advantages of simple and compact structure, convenient use and maintenance.

2. It has good self-priming, so it is not necessary to fill the liquid before starting the pump.

3. Lubrication is achieved automatically by conveying liquid, so there is no need to add lubricating fluid in daily work.

4. The small deviation caused by installation can be compensated by using elastic coupling to transmit power. When the oil pump is subjected to inevitable hydraulic impact, it can play a good buffer role.

3、 KCB gear oil pump structure description:

KCB gear pump body, gear, front and rear pump cover, safety valve, bearing and sealing device, etc

1. Pump body, front and rear cover are gray cast iron parts, gears are made of high-quality carbon steel; copper or stainless steel can be used according to user's needs.

2. Safety valve. KCB series oil pump is equipped with safety valve above the rear pump cover or pump body. When the pump or discharge pipe fails or the discharge valve is completely closed, resulting in high pressure and high pressure impact, the safety valve will automatically open, remove part or all of the high pressure liquid and return to the suction chamber, thus playing a safety protection role for the pump and pipeline.

3. Bearings. All 2CY series oil pumps adopt Du bearing; tin bronze bearing can be used according to user's requirements. &0818.3-83.3, 2cy1.1 gear oil pump adopts Du bearing; tin bronze bearing can be used according to user requirements.

4. Shaft seal. The shaft end seal of this series gear oil pump has three kinds of structure: skeleton oil seal, mechanical seal and packing seal.

a. Skeleton oil seal: the features of framework oil seal are convenient maintenance and replacement, low cost, but short service life. NBR skeleton oil seal is suitable for 1001: the following working environment; fluororubber framework oil seal is suitable for working environment below 200 ℃.

b. Mechanical seal: mechanical seal is characterized by reliable seal, long service life and high cost. The matrix of mechanical seal is made of stainless steel. The dynamic and static media are made of YG8 cemented carbide or YG8 graphite respectively. The service temperature is below 200 ℃.

c. Packing seal: packing seal is only used for high temperature oil pump, which is characterized by high temperature resistance and a small amount of leakage. In the process of use, it needs to be adjusted according to the leakage, and the service temperature is below 250 ℃.

What type of sealing structure the user needs should be indicated when ordering. Those not specified in the order shall be supplied according to the structure of NBR skeleton oil seal.

5. Oil inlet and outlet type:

The inlet and outlet of 2CY series gear oil pump are British pipe thread (g) corresponding to the diameter, which are directly made on the pump body.

Kcb18.3-200, 2cy1.1-12 gear type oil pump is equipped with waist flange with pipe thread port; other pumps are not equipped with flange, when the user needs to be equipped with flange, it should be noted in the order.

6. The pump and motor are connected by elastic coupling and installed on the common chassis.

4、 Precautions for KCB gear oil pump

1. Install gear oil pump:

a. Before installation, check whether the pump is damaged during transportation, such as whether the motor is damp, whether the dust cover at the pump inlet and outlet is damaged, which causes dirt to enter the pump cavity, etc.

b. Before installing the pipeline, the inner wall of the pipe should be cleaned with water or steam. During installation, the weight of the pipeline should be avoided to be borne by the pump, so as not to affect the accuracy and service life of the pump.

c. The gear oil pump should be close to the oil pool as far as possible; there should be no air or liquid leakage at the connecting parts of the pipeline, otherwise the phenomenon that liquid can not be absorbed will occur.

d. In order to prevent impurities such as particles from entering the pump, a metal filter screen should be installed at the suction port, with a filtration accuracy of 30 mesh / in, and the filtering area should be more than three times of the cross-sectional area of the oil inlet pipe.

e. It is recommended to install vacuum gauge and pressure gauge on the inlet and outlet pipelines to monitor the working state of the pump.

f. When the oil pool is deep, the oil suction pipeline is long or the medium viscosity is high, the oil inlet pipe can be thickened by one gear. When the oil suction pipeline is long, the bottom valve should also be installed.

2. Inspection before operation of gear oil pump:

a. Whether the fasteners of the pump are firm.

b. Whether the driving shaft rotates evenly.

c. Whether the valve in and out of the pipeline is open.

d. Whether the rotation direction of the pump meets the requirements.

e. Proper amount of medium should be injected into the pump before initial use.

3. Maintenance of gear oil pump during operation:

a. Note that the readings of the pressure gauge and vacuum gauge of the gear oil pump should be within the technical specifications specified by the pump.

b. When the gear oil pump has abnormal noise or high temperature rise in operation, the pump should be stopped immediately for inspection.

c. Generally, it is not allowed to adjust the safety valve arbitrarily. If it is necessary to adjust, the instrument should be used for calibration. Make the cut-off pressure of the safety valve as the pump

d. 1.5-2 times of rated pressure. 4. Pump stop

a. Turn off the power.

b. Close the inlet and outlet valves.

Kcb133-960, 2cy8-60 gear type oil pump has three types of structure: Du bearing, tin bronze bearing and rolling bearing, which should be noted when ordering. If not specified in the order, they shall be supplied according to Du bearing structure.

The bearings are built-in type and lubricated by the transported medium; 011 bearing and tin bronze bearing can work in non lubricating medium.

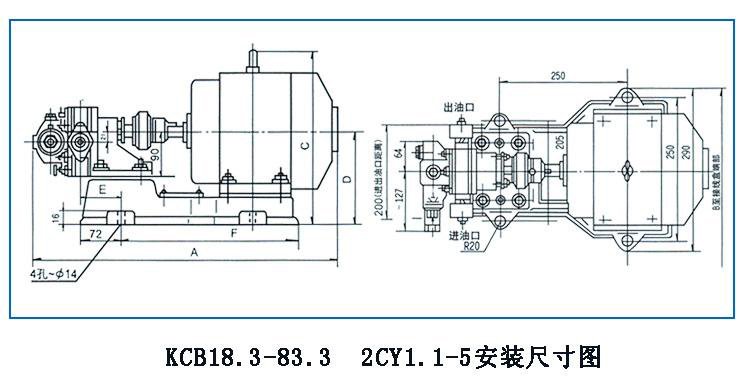

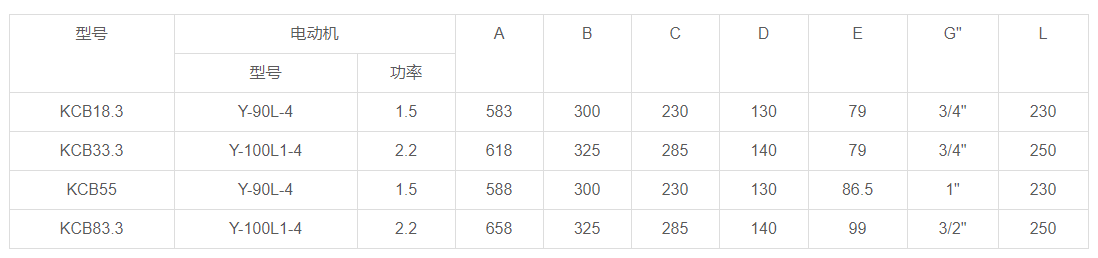

model | flow m3/h | pressure MPa | vacuum degree (m.H2O) | In and out diameter (mm) | H | L | L1 | L2 | L3 | A | B | C | D | n-m | Distance between entrance and exit K | Matching motor model | power KW |

KCB18.3 2CY1.1/14.5 | 1.1 | 1.45 | 5 | G3/4″ | 109 | 583 | 405 | 72 | 250 | 205 | 250 | 79 | – | – | 200 | Y90L-4 | 1.5 |

KCB33.3 2CY2/14.5 | 2 | 1.45 | 5 | G3/4″ | 119 | 618 | 437 | 72 | 250 | 205 | 250 | 79 | – | – | 200 | Y100L1-4 | 2.2 |

KCB55 2CY3.3/3.3 | 3.3 | 0.33 | 5 | G1″ | 109 | 588 | 405 | 72 | 250 | 205 | 250 | 86 | – | – | 200 | Y90L-4 | 1.5 |

KCB83.3 2CY5/3.3 | 5 | 0.33 | 5 | G11/2″ | 119 | 658 | 437 | 72 | 250 | 205 | 250 | 99 | – | – | 200 | Y100L2-4 | 2.2 |

KCB133 2CY8/3.3 | 8 | 0.33 | 5 | G2″ | 182 | 778 | 688 | 130 | 450 | 250 | 340 | 32 | – | – | 260 | Y132S-6 | 3 |

2CY8/6 | 8 | 0.6 | 5 | G2″ | 182 | 818 | 688 | 130 | 450 | 250 | 340 | 32 | – | – | 260 | Y132M1-6 | 4 |

2CY8/10 | 8 | 1.0 | 5 | G2″ | 182 | 818 | 688 | 130 | 450 | 250 | 340 | 32 | – | – | 260 | Y132M2-6 | 5.5 |

2CY12/1.3 | 12 | 0.13 | 5 | G2″ | 172 | 703 | 576 | 130 | 370 | 250 | 305 | 32 | – | – | 260 | Y112M-4 | 4 |

KCB200 2CY12/3.3 | 12 | 0.33 | 5 | G2″ | 182 | 778 | 688 | 130 | 450 | 250 | 340 | 32 | – | – | 260 | Y132S-4 | 5.5 |

2CY12/6 | 12 | 0.6 | 5 | G2″ | 182 | 778 | 688 | 130 | 450 | 250 | 340 | 32 | – | – | 260 | Y132S-4 | 5.5 |

2CY12/10 | 12 | 1.0 | 5 | G2″ | 182 | 818 | 688 | 130 | 450 | 250 | 340 | 32 | – | – | 260 | Y132M-4 | 7.5 |

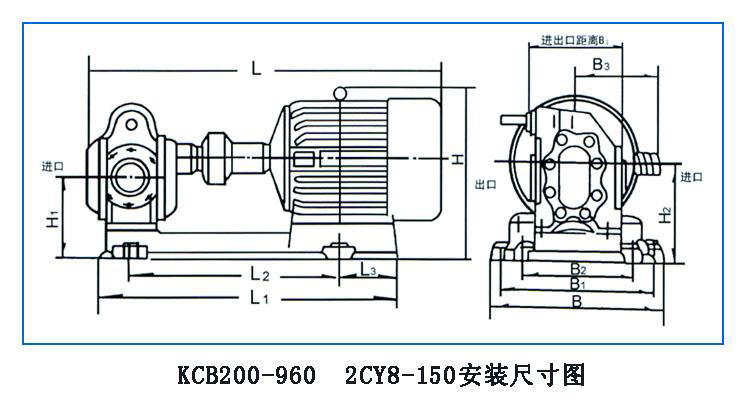

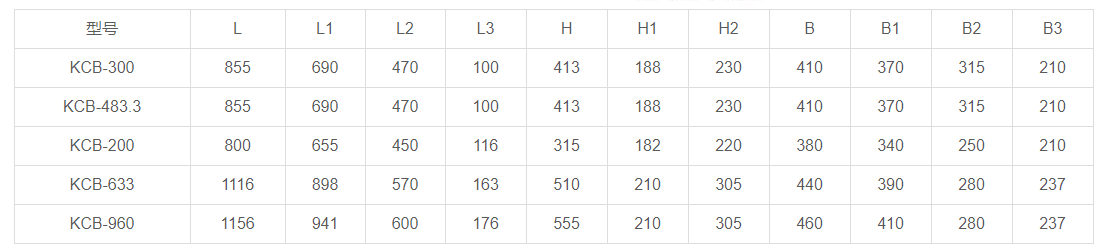

KCB300 2CY18/3.6 | 18 | 0.36 | 5 | 70 | 187 | 898 | 723 | 120 | 480 | 280 | 340 | 45 | 123 | 6-M14 | 234 | Y132M2-6 | 5.5 |

2CY18/6 | 18 | 0.6 | 5 | 70 | 242 | 983 | 912 | 155 | 600 | 280 | 380 | 30 | 123 | 6-M14 | 234 | Y160M-6 | 7.5 |

KCB483 2CY29/3.6 | 29 | 0.36 | 5 | 70 | 187 | 898 | 723 | 120 | 480 | 280 | 340 | 45 | 123 | 6-M14 | 234 | Y132M-4 | 7.5 |

2CY29/6 | 29 | 0.6 | 5 | 70 | 242 | 983 | 912 | 155 | 600 | 280 | 380 | 30 | 123 | 6-M14 | 234 | Y160M-4 | 11 |

KCB633 2CY38/2.8 | 38 | 0.28 | 5 | 100 | 230 | 1094 | 912 | 155 | 600 | 280 | 380 | 60 | 158 | 8-M16 | 280 | Y160L-6 | 11 |

2CY38/6 | 38 | 0.6 | 5 | 100 | 286 | 1224 | 943 | 150 | 650 | 360 | 360 | 65 | 158 | 8-M16 | 280 | Y200L2-6 | 22 |

KCB960 2CY60/3 | 60 | 0.3 | 5 | 100 | 230 | 1159 | 955 | 155 | 650 | 280 | 410 | 60 | 158 | 8-M16 | 280 | Y180L-4 | 22 |

2CY100/3 | 100 | 0.3 | 5 | 150 | 440 | 1586 | 1325 | 110 | 550×2 | 450 | 450 | -20 | 210 | 8-M16 | 400 | Y250M-8 | 30 |

2CY100/6 | 100 | 0.6 | 5 | 150 | 465 | 1856 | 1536 | 138 | 420×3 | 600 | 600 | 8 | 210 | 8-M16 | 400 | Y315S-8 | 55 |

2CY120/3 | 120 | 0.3 | 5 | 150 | 440 | 1586 | 1325 | 110 | 550×2 | 450 | 450 | -20 | 210 | 8-M16 | 400 | Y250M-8 | 30 |

2CY120/6 | 120 | 0.6 | 5 | 150 | 465 | 1856 | 1536 | 138 | 420×3 | 600 | 600 | 8 | 210 | 8-M16 | 400 | Y315S-8 | 55 |

2CY150/3 | 150 | 0.3 | 5 | 150 | 460 | 1696 | 1376 | 138 | 550×2 | 500 | 500 | 8 | 210 | 8-M16 | 400 | Y280S-8 | 37 |

2CY150/6 | 150 | 0.6 | 5 | 150 | 465 | 1946 | 1536 | 138 | 420×3 | 600 | 600 | 8 | 210 | 8-M16 | 400 | Y315M1-8 | 75 |

注:1、表中参数为50℃,30C.S.t粘度条件下的数值。 2、KCB18.3~200、2CY1.1~12配带管螺纹口的腰形法兰;

KCB300~960、2CY18~150不配带法兰,需用户自行加工。

KCB gear oil pump usage Description:

KCB gear pump is suitable for conveying all kinds of oil, such as heavy oil, diesel oil and lubricating oil. With copper gear, it can transport low-point liquid, such as gas oil and benzene, so it is called gear oil pump. Stainless steel gear pump can transport drinks and corrosive liquids. The viscosity is 5 × 10 - 5 ~ 1.5 × 103m2 / s. The temperature is not high at 70 ℃. If it is necessary to transport high temperature liquid, please use high temperature resistant gear oil pump for single-stage single oil suction pump, which can transport liquid below 300 ℃.

It can be used for lubricating oil, heavy oil, industrial light oil, edible oil and other oils containing solid particles and fibers. It is suitable for oil depot, wharf, ship, factory, farm, mine, etc.