Product overview

GW type non clogging pipeline sewage pump is a new generation of pump products developed on the basis of introducing foreign advanced technology and combining with the use characteristics of domestic water pump. It has the characteristics of remarkable energy saving effect, anti winding, no blockage, automatic installation and automatic control. It has unique effect in discharging solid particles and long fiber waste.

This series of pumps adopt unique impeller structure and new mechanical seal, which can effectively transport solids and long fibers. Compared with the traditional impeller, the impeller of the pump adopts the form of single channel or double channel, which is similar to an elbow with the same cross-section size, and has very good flow capacity. With reasonable volute chamber, the pump has high efficiency. After the dynamic and static balance test of the impeller, the pump has no vibration in operation.

Product features

1. The pump and motor are directly connected and coaxial, belonging to mechatronics products, with compact structure and stable performance.

2. The design of anti clogging hydraulic components in large flow channel greatly improves the ability of dirt passing through. It can effectively pass 5 times of the diameter of the pump and the solid particles with the diameter of about 50% of the pump diameter.

3. Reasonable design, reasonable matching motor, high efficiency, low noise and remarkable energy saving effect.

4. The mechanical seal is made of hard wear-resistant tungsten carbide, which is durable and wear-resistant. It can make the pump operate safely and continuously for more than 8000 hours.

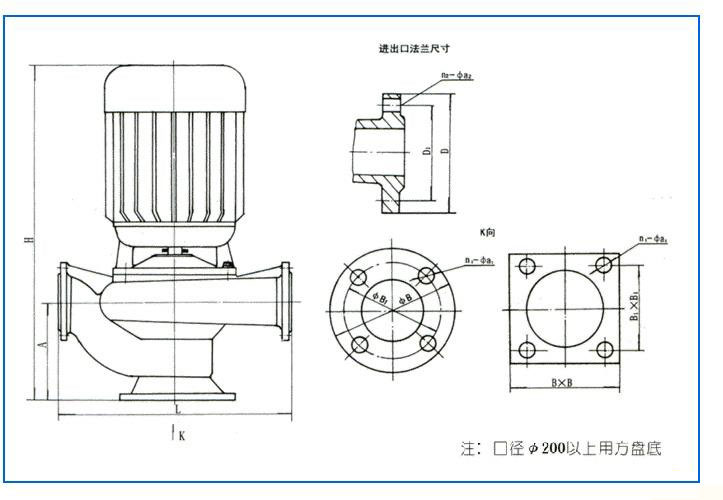

5. The pump is vertical structure, the center line of inlet and outlet is in the same horizontal line, and the specifications of inlet and outlet flange are the same, so the installation and disassembly are very convenient.

6. With small floor area and no need to build a computer room, it can save a lot of capital construction costs; with a protective cover on the wind blade end of the motor, the whole machine can be placed outdoors.

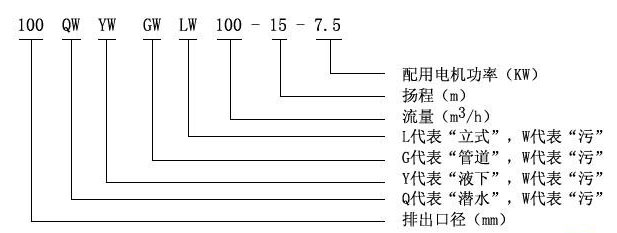

Model meaning

model | Caliber (mm) | Flow (m3/h) | Lift (m) | Power (kw) | Rotational speed (r/min) | Efficiency (%) |

GW25-8-22-1.1 | 25 | 8 | 22 | 1.1 | 2825 | 38.5 |

GW32-12-15-1.1 | 32 | 12 | 15 | 1.1 | 2825 | 40 |

GW40-15-15-1.5 | 40 | 15 | 15 | 1.5 | 2840 | 45.1 |

GW40-15-30-2.2 | 40 | 15 | 30 | 2.2 | 2840 | 48 |

GW50-20-7-0.75 | 50 | 20 | 7 | 0.75 | 1390 | 54 |

GW50-10-10-0.75 | 50 | 10 | 10 | 0.75 | 2900 | 56 |

GW50-20-15-1.5 | 50 | 20 | 15 | 1.5 | 2840 | 55 |

GW50-15-25-2.2 | 50 | 15 | 25 | 2.2 | 2840 | 56 |

GW50-18-30-3 | 50 | 18 | 30 | 3 | 2880 | 58 |

GW50-25-32-5.5 | 50 | 25 | 32 | 5.5 | 2900 | 53 |

GW50-20-40-7.5 | 50 | 20 | 40 | 7.5 | 2900 | 55 |

GW65-25-15-2.2 | 65 | 25 | 15 | 2.2 | 2840 | 52 |

GW65-37-13-3 | 65 | 37 | 13 | 3 | 2880 | 55 |

GW65-25-30-4 | 65 | 25 | 30 | 4 | 2890 | 58 |

GW65-30-40-7.5 | 65 | 30 | 40 | 7.5 | 2900 | 56 |

GW65-35-50-11 | 65 | 35 | 50 | 11 | 2930 | 60 |

GW65-35-60-15 | 65 | 35 | 60 | 15 | 2930 | 63 |

GW80-40-7-2.2 | 80 | 40 | 7 | 2.2 | 1420 | 52 |

GW80-43-13-3 | 80 | 43 | 13 | 3 | 2880 | 50 |

GW80-40-15-4 | 80 | 40 | 15 | 4 | 2890 | 57 |

GW80-65-25-7.5 | 80 | 65 | 25 | 7.5 | 2900 | 56 |

GW100-80-10-4 | 100 | 80 | 10 | 4 | 1440 | 62 |

GW100-110-10-5.5 | 100 | 110 | 10 | 5.5 | 1440 | 66 |

GW100-100-15-7.5 | 100 | 100 | 15 | 7.5 | 1440 | 67 |

GW100-85-20-7.5 | 100 | 85 | 20 | 7.5 | 1440 | 68 |

GW100-100-25-11 | 100 | 100 | 25 | 11 | 1460 | 65 |

GW100-100-30-15 | 100 | 100 | 30 | 15 | 1460 | 66 |

GW100-100-35-18.5 | 100 | 100 | 35 | 18.5 | 1470 | 65 |

GW125-130-15-11 | 125 | 130 | 15 | 11 | 1460 | 62 |

GW120-130-20-15 | 125 | 130 | 20 | 15 | 1460 | 63 |

GW150-145-9-7.5 | 150 | 145 | 9 | 7.5 | 1440 | 63 |

GW150-180-15-15 | 150 | 180 | 15 | 15 | 1460 | 65 |

GW150-180-20-18.5 | 150 | 180 | 20 | 18.5 | 1470 | 75 |

GW150-180-25-22 | 150 | 180 | 25 | 22 | 1470 | 76 |

GW150-130-30-22 | 150 | 130 | 30 | 22 | 1470 | 75 |

GW150-180-30-30 | 150 | 180 | 30 | 30 | 1470 | 73 |

GW150-200-30-37 | 150 | 200 | 30 | 37 | 1480 | 70 |

GW200-300-7-11 | 200 | 300 | 7 | 11 | 970 | 73 |

GW200-250-11-15 | 200 | 250 | 11 | 15 | 970 | 74 |

GW200-400-10-22 | 200 | 400 | 10 | 22 | 1470 | 76 |

GW200-400-13-30 | 200 | 400 | 13 | 30 | 1470 | 73 |

GW200-250-15-18.5 | 200 | 250 | 15 | 18.5 | 1470 | 72 |

GW200-300-15-22 | 200 | 300 | 15 | 22 | 1470 | 73 |

GW200-250-22-30 | 200 | 250 | 22 | 30 | 1470 | 71 |

GW200-350-25-37 | 200 | 350 | 25 | 37 | 1980 | 75 |

GW200-400-30-55 | 200 | 400 | 30 | 55 | 1480 | 70 |

GW250-600-9-30 | 250 | 600 | 9 | 30 | 980 | 74 |

GW250-600-12-37 | 250 | 600 | 12 | 37 | 1480 | 78 |

GW250-600-15-45 | 250 | 600 | 15 | 45 | 1480 | 75 |

GW250-600-20-55 | 250 | 600 | 20 | 55 | 1480 | 73 |

GW250-600-25-75 | 250 | 600 | 25 | 75 | 1480 | 73 |

GW300-800-12-45 | 300 | 800 | 12 | 45 | 980 | 76 |

GW300-500-15-45 | 300 | 500 | 15 | 45 | 980 | 70 |

GW300-800-15-55 | 300 | 800 | 15 | 55 | 980 | 73 |

GW300-600-20-55 | 300 | 600 | 20 | 55 | 980 | 75 |

GW300-800-20-75 | 300 | 800 | 20 | 75 | 980 | 78 |

GW300-950-20-90 | 300 | 950 | 20 | 90 | 980 | 80 |

GW300-1000-25-110 | 300 | 1000 | 25 | 110 | 980 | 82 |

GW350-1100-10-55 | 350 | 1100 | 10 | 55 | 980 | 84.5 |

GW350-1500-15-90 | 350 | 1500 | 15 | 90 | 980 | 82.5 |

GW350-1200-18-90 | 350 | 1200 | 18 | 90 | 980 | 83.1 |

GW350-1100-28-132 | 350 | 1100 | 28 | 132 | 740 | 83.2 |

GW350-1000-36-160 | 350 | 1000 | 36 | 160 | 740 | 78.5 |

GW400-1500-10-75 | 400 | 1500 | 10 | 75 | 980 | 82.1 |

GW400-2000-15-132 | 400 | 2000 | 15 | 132 | 740 | 85.5 |

GW400-1700-22-160 | 400 | 1700 | 22 | 160 | 740 | 82.1 |

GW400-1500-26-160 | 400 | 1500 | 26 | 160 | 740 | 83.5 |

GW400-1700-30-200 | 400 | 1700 | 30 | 200 | 740 | 83.5 |

GW400-1800-32-250 | 400 | 1800 | 32 | 250 | 740 | 82.1 |

GW500-2500-10-110 | 500 | 2500 | 10 | 110 | 740 | 82 |

GW500-2600-15-160 | 500 | 2600 | 15 | 160 | 740 | 83 |

GW500-2400-22-220 | 500 | 2400 | 22 | 220 | 740 | 84 |

GW500-2600-24-250 | 500 | 2600 | 24 | 250 | 740 | 82 |

1、 Application of GW pipeline type non clogging sewage pump

GW type pipeline non blocking sewage pump is suitable for the discharge of industrial and commercial seriously polluted wastewater, sewage discharge station of residential area, drainage system of urban sewage treatment plant, drainage station of civil air defense system, water supply equipment of waterworks, sewage discharge of hospitals and hotels, municipal engineering construction site, exploration, mine auxiliary equipment, rural biogas digester, farmland irrigation and other industries It can also be used for clean water and weak corrosive medium.

4、 Service conditions of GW pipeline type non clogging sewage pump:

A. The operating environment temperature of the pump is ≤ 40 ℃, the humidity is ≤ 95%; the altitude is less than or equal to 1000m, and it should be put forward when ordering.

B. The temperature of the medium is not more than 60 ℃, and the medium weight is 1-1.3kg/dm3.

C. The application range of cast iron material is ph5-9.

D. 1Crl8Ni9Ti stainless steel material can use general corrosive medium.

E. The altitude of using environment is not more than 1000 meters, and it should be put forward when ordering, so as to provide you with more reliable products.

Note: if users have special requirements for temperature and medium, please indicate the details of conveying medium when ordering, so as to provide more reliable products.

2、 Installation and use of GW pipeline type non blocking sewage pump:

1. First check whether the external fasteners are loose during transportation.

2. Check whether the power supply voltage meets the requirements of motor name plate.

3. Turn on the power supply for a trial run to see whether the impeller rotates according to the direction indicated by the upper finger of the pump. If the direction is reversed, adjust any two-phase lines in the cable. The test run time should not be too long to avoid burning the seal.

4. Install the pump and start it up. It is better to install the screw of pump foot.

3、 Inspection and maintenance of GW pipeline type non blocking sewage pump:

1. Before using the pump, the insulation resistance of the motor winding to the casing should be checked. If it is lower than 0.5 megohm, the stator must be dried just before it can be used.

2. If the clearance between impeller and oil seal at the inlet of pump body exceeds 2mm, wear-resistant oil seal shall be replaced.

3. In case of water leakage in the pump seal, the seal shall be replaced in time. During replacement, the static seal shall be installed flat and solid, and then the dynamic seal shall be sealed on the shaft.

4. When replacing the impeller, pull it out with a puller instead of striking it with a hammer to avoid damaging the axial degree.

4、 Causes of common failures of GW pipeline type non clogging sewage pump are as follows:

1. There is no water, and the gravity and particle size of the pumped liquid are too high; the liquid channel is blocked; the impeller is turned wrong; the impeller is stuck when the bar material is drawn into; the outlet height of the pipe exceeds the rated head height.

2. Insufficient flow and low lift. The results show that the voltage is low, the impeller is in wrong direction or the seal is worn; the heavy particle size of liquid is too high.

3. The insulation resistance is low, the surrounding environment is humid, and the mechanical seal is seriously leaking.