Product overview

YW type non clogging submerged sewage pump is a new generation of pump products successfully developed on the basis of introducing foreign advanced technology and combining with the use characteristics of domestic water pump. It has the characteristics of remarkable energy saving effect, anti winding, no blockage, automatic installation and automatic control. It has unique effect in discharging solid particles and long fiber waste.

This series of pumps adopt unique impeller structure and new mechanical seal, which can effectively transport solids and long fibers. Compared with the traditional impeller, the impeller of the pump adopts the form of single channel or double channel, which is similar to an elbow with the same cross-section size, and has very good flow capacity. With reasonable volute chamber, the pump has high efficiency. After the dynamic and static balance test of the impeller, the pump has no vibration in operation.

Product features

1. The unique single or double blade impeller structure greatly improves the dirt carrying capacity, which can effectively pass 5 times the diameter of the pump and the solid particles with the diameter of about 50% of the pump diameter.

2。 The mechanical seal is made of new hard and corrosion-resistant tungsten titanium material, which can make the pump operate safely and continuously for more than 8000 hours.

3. The overall structure is compact, small volume, low noise, remarkable energy-saving effect, convenient maintenance, no need to build pump house, can work in the water, greatly reducing the project cost.

4. The pump is compact in structure, small in size, easy to move and easy to install.

5. Can be equipped with liquid level automatic control cabinet, according to the required liquid level changes, automatic control of pump start and stop, no need for special care, very convenient to use.

6. The pump is of vertical structure. When working, the pump body is immersed in liquid, so it is easy to start. There is no exhaust and evacuation problem. At the same time, it has the characteristics of no leakage, and the depth under the liquid can reach 15 meters.

7. The shaft connection structure is advanced and reliable. The pump and motor are connected by coupling device. The pump shaft size is precise, which ensures the stable operation of the pump and leaves enough safety factor.

8. There are two kinds of pump installation: single pipe installation and double pipe installation. The supporting parts are disc and square plate installation, which are suitable for different needs.

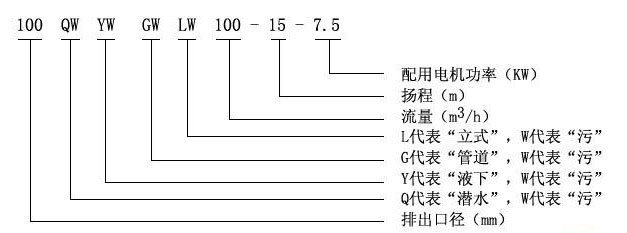

Model meaning

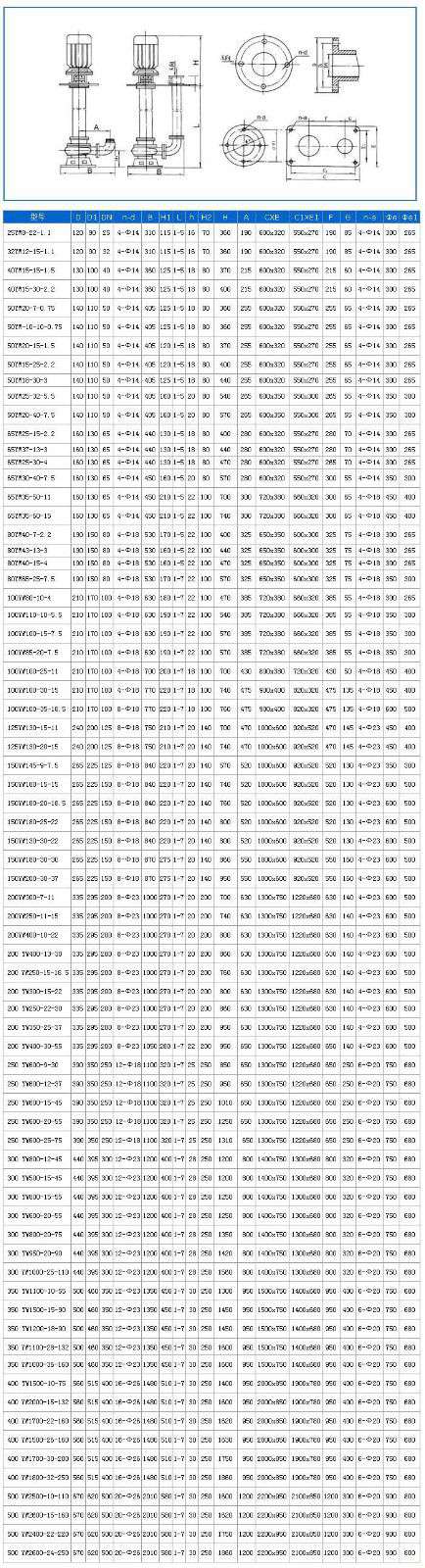

model | Caliber (mm) | Flow (m3/h) | Lift (m) | Power (kw) | Rotational speed (r/min) | Efficiency (%) |

YW25-8-22-1.1 | 25 | 8 | 22 | 1.1 | 2825 | 38.5 |

YW32-12-15-1.1 | 32 | 12 | 15 | 1.1 | 2825 | 40 |

YW40-15-15-1.5 | 40 | 15 | 15 | 1.5 | 2840 | 45.1 |

YW40-15-30-2.2 | 40 | 15 | 30 | 2.2 | 2840 | 48 |

YW50-20-7-0.75 | 50 | 20 | 7 | 0.75 | 1390 | 54 |

YW50-10-10-0.75 | 50 | 10 | 10 | 0.75 | 1390 | 56 |

YW50-20-15-1.5 | 50 | 20 | 15 | 1.5 | 2840 | 55 |

YW50-15-25-2.2 | 50 | 15 | 25 | 2.2 | 2840 | 56 |

YW50-18-30-3 | 50 | 18 | 30 | 3 | 2880 | 58 |

YW50-25-32-5.5 | 50 | 25 | 32 | 5.5 | 2900 | 53 |

YW50-20-40-7.5 | 50 | 20 | 40 | 7.5 | 2900 | 55 |

YW65-25-15-2.2 | 65 | 25 | 15 | 2.2 | 2840 | 52 |

YW65-37-13-3 | 65 | 37 | 13 | 3 | 2880 | 55 |

YW65-25-30-4 | 65 | 25 | 30 | 4 | 2890 | 58 |

YW65-30-40-7.5 | 65 | 30 | 40 | 7.5 | 2900 | 56 |

YW65-35-50-11 | 65 | 35 | 50 | 11 | 2930 | 60 |

YW65-35-60-15 | 65 | 35 | 60 | 15 | 2930 | 63 |

YW80-40-7-2.2 | 80 | 40 | 7 | 2.2 | 1420 | 52 |

YW80-43-13-3 | 80 | 43 | 13 | 3 | 2880 | 50 |

YW80-40-15-4 | 80 | 40 | 15 | 4 | 2890 | 57 |

YW80-65-25-7.5 | 80 | 65 | 25 | 7.5 | 2900 | 56 |

YW100-80-10-4 | 100 | 80 | 10 | 4 | 1440 | 62 |

YW100-110-10-5.5 | 100 | 110 | 10 | 5.5 | 1440 | 66 |

YW100-100-15-7.5 | 100 | 100 | 15 | 7.5 | 1440 | 67 |

YW100-85-20-7.5 | 100 | 85 | 20 | 7.5 | 1440 | 68 |

YW100-100-25-11 | 100 | 100 | 25 | 11 | 1460 | 65 |

YW100-100-30-15 | 100 | 100 | 30 | 15 | 1460 | 66 |

YW100-100-35-18.5 | 100 | 100 | 35 | 18.5 | 1470 | 65 |

YW125-130-15-11 | 125 | 130 | 15 | 11 | 1460 | 62 |

YW120-130-20-15 | 125 | 130 | 20 | 15 | 1460 | 63 |

YW150-145-9-7.5 | 150 | 145 | 9 | 7.5 | 1440 | 63 |

YW150-180-15-15 | 150 | 180 | 15 | 15 | 1460 | 65 |

YW150-180-20-18.5 | 150 | 180 | 20 | 18.5 | 1470 | 75 |

YW150-180-25-22 | 150 | 180 | 25 | 22 | 1470 | 76 |

YW150-130-30-22 | 150 | 130 | 30 | 22 | 1470 | 75 |

YW150-180-30-30 | 150 | 180 | 30 | 30 | 1470 | 73 |

YW150-200-30-37 | 150 | 200 | 30 | 37 | 1480 | 70 |

YW200-300-7-11 | 200 | 300 | 7 | 11 | 970 | 73 |

YW200-250-11-15 | 200 | 250 | 11 | 15 | 970 | 74 |

YW200-400-10-22 | 200 | 400 | 10 | 22 | 1470 | 76 |

YW200-400-13-30 | 200 | 400 | 13 | 30 | 1470 | 73 |

YW200-250-15-18.5 | 200 | 250 | 15 | 18.5 | 1470 | 72 |

YW200-300-15-22 | 200 | 300 | 15 | 22 | 1470 | 73 |

YW200-250-22-30 | 200 | 250 | 22 | 30 | 1470 | 71 |

YW200-350-25-37 | 200 | 350 | 25 | 37 | 1980 | 75 |

YW200-400-30-55 | 200 | 400 | 30 | 55 | 1480 | 70 |

YW250-600-9-30 | 250 | 600 | 9 | 30 | 980 | 74 |

YW250-600-12-37 | 250 | 600 | 12 | 37 | 1480 | 78 |

YW250-600-15-45 | 250 | 600 | 15 | 45 | 1480 | 75 |

YW250-600-20-55 | 250 | 600 | 20 | 55 | 1480 | 73 |

YW250-600-25-75 | 250 | 600 | 25 | 75 | 1480 | 73 |

YW300-800-12-45 | 300 | 800 | 12 | 45 | 980 | 76 |

YW300-500-15-45 | 300 | 500 | 15 | 45 | 980 | 70 |

YW300-800-15-55 | 300 | 800 | 15 | 55 | 980 | 73 |

YW300-600-20-55 | 300 | 600 | 20 | 55 | 980 | 75 |

YW300-800-20-75 | 300 | 800 | 20 | 75 | 980 | 78 |

YW300-950-20-90 | 300 | 950 | 20 | 90 | 980 | 80 |

YW300-1000-25-110 | 300 | 1000 | 25 | 110 | 980 | 82 |

YW350-1100-10-55 | 350 | 1100 | 10 | 55 | 980 | 84.5 |

YW350-1500-15-90 | 350 | 1500 | 15 | 90 | 980 | 82.5 |

YW350-1200-18-90 | 350 | 1200 | 18 | 90 | 980 | 83.1 |

YW350-1100-28-132 | 350 | 1100 | 28 | 132 | 740 | 83.2 |

YW350-1000-36-160 | 350 | 1000 | 36 | 160 | 740 | 78.5 |

YW400-1500-10-75 | 400 | 1500 | 10 | 75 | 980 | 82.1 |

YW400-2000-15-132 | 400 | 2000 | 15 | 132 | 740 | 85.5 |

YW400-1700-22-160 | 400 | 1700 | 22 | 160 | 740 | 82.1 |

YW400-1500-26-160 | 400 | 1500 | 26 | 160 | 740 | 83.5 |

YW400-1700-30-200 | 400 | 1700 | 30 | 200 | 740 | 83.5 |

YW400-1800-32-250 | 400 | 1800 | 32 | 250 | 740 | 82.1 |

YW500-2500-10-110 | 500 | 2500 | 10 | 110 | 740 | 82 |

YW500-2600-15-160 | 500 | 2600 | 15 | 160 | 740 | 83 |

YW500-2400-22-220 | 500 | 2400 | 22 | 220 | 740 | 84 |

YW500-2600-24-250 | 500 | 2600 | 24 | 250 | 740 | 82 |

Main uses

It can be used in chemical industry, petroleum industry, pharmaceutical industry, mining industry, paper industry, cement plant, steel plant, power plant, coal processing industry, urban sewage treatment plant drainage system, municipal engineering, construction site and other industries. It is also used for pumping clean water and corrosive media.